Specially formulated Molecular Sieve Zeolite for adsorption

of the water vapor in insulating glass to improve sound Insulation and

heat insulation of glass.

- Formulated for use in insulating glass production in coherence with solvent-free sealents.

- The pore openings in the material have diameter of approximately 30A which ensures it does not adsorb air nor gases such as argon or SF6.

- The slow adsorption process promotes achievement of low dew point Temperatures over a very long period of time.

- Glass panes filled with Molecular Sieves are protected against pane deflections and glass breakage

- Suitable for air as well as gas filled units.

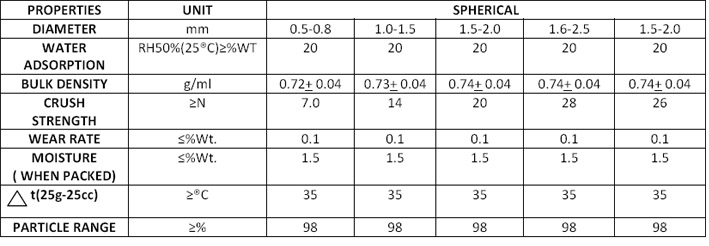

- A small and controlled bead size facilitates is usage in narrow insulating glass profiles

- Store in a cool and dry place away from air and moisture

- Do not keep the packs in open condition. Re-pack tightly after use.

- Do not expose to acids or alkali environment

- (All packing strapped and stretch wrapped on wooden pallets)

- 1200 Kg. Super sack

- 25 Kg. bags in cartons (vacuum packed)

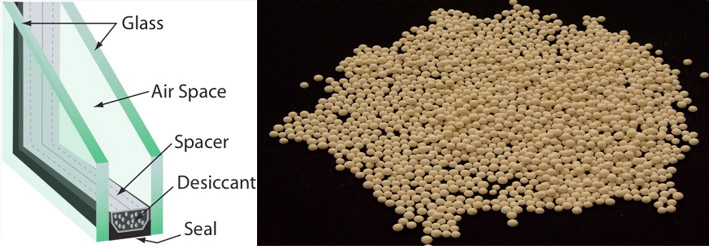

Molecular sieves work to maintain the proper dew point of the space between the inner and outer panes of glass.

This is achieved through the specific adsorption of water and solvents introduced during IG unit manufacturing or penetrating into the interspace during the service time of the IG unit.

Molecular sieves are also engineered to minimize pressure changes which can eventually lead to unit failure.

The benefits of Molecular Sleeve adsorbents are:

- High water adsorption capacity

- Low dew point

- Longer unit life

- Compatibility with all gases and sealants

- Compliance with all filling systems

- Beaded products for loose fill spacer systems

- Special beaded grades to prevent fogging

- Hot melt matrix product for intercept lines

- Recyclable packages for optimum handling

- Compliance with national and international test standards

- Low dust and attrition

- Low gas desorption