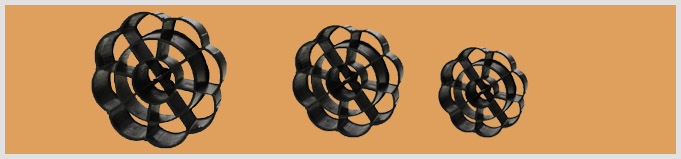

Coarse bubble diffuser is suitable for equalization tank in waste water treatment plans for mixing purpose. It is the method of oxygenating water and is applicable in Air Stripping, Small or Package Plant Systems, Auto-thermophilic Aerobic Digestion(ATAD), Mechanically Thickened Sludge Applications and Aerobic Digestion Applications. Easy to install and operate, it require low maintanance and allows application flexibility and mechanical reliability. Membrane material is EPDM.

Read More»

Diffuser / Fab Products

Aquaflex diffusers innovative design is the most efficient and cost effective on the market. It has been designed to increase performance and decrease utility costs. The higher oxygen transfer efficiencies will also permit greater process flows and improved quality.

Floating media can be utilized in new or old bio reactors and enhance performance. Once the media is placed inside a bio reactor and set in proper operation, you have a complete stable, clog-free bio-film reactor.

Microorganisms, which are attached to the floating media reduce the organic load. This is a fixed-film process where the floating media become carriers that build a floating bed in the water(The Bio Film) and stabilize WWTP.

Read More»

Fill pack media randomly picked PP filter media has a wide application in biological treatment systems. The reactors are up-flow or down-flow fixed film or floating type, based on either aerobic or anaerobic treatment systems. The media provides optimum effective surface area for biological growth. The three dimensional liquid distribution due to unique dimensional design, increases hydraulic retention time and ensures excellent gas-liquid distribution within the packed bed reactor and thus enhancing the treatment efficiency.

The filter press is a solid liquid seperation device using the principle of pressure feeding. It has been used successfully in almost every industrial filtration application for many years. It includes a series of filter plates and frames or recessed plates which are arranged alternately. The filter medium is provided in between the plates. A feeding pump is utilized to force the liquid through the medium leaving the solid trapped inside. Compared to other pressure filters the filter press holds more solids per square feet of filtering surface area than any other. A closer is required which will be manual operated. The closer containing a controlling a follower plate presses the plates together, creating a sealed unit. The filter press is typically less costly to install than compared to rotary drum vaccum filters, belt presses or centrifiguges. It is significantly less expensive and easier to maintain and operate then the other three, and service life has been proven and time again to be longer.

The filter press is a solid liquid seperation device using the principle of pressure feeding. It has been used successfully in almost every industrial filtration application for many years. It includes a series of filter plates and frames or recessed plates which are arranged alternately. The filter medium is provided in between the plates. A feeding pump is utilized to force the liquid through the medium leaving the solid trapped inside. Compared to other pressure filters the filter press holds more solids per square feet of filtering surface area than any other. A closer is required which will be manual operated. The closer containing a controlling a follower plate presses the plates together, creating a sealed unit. The filter press is typically less costly to install than compared to rotary drum vaccum filters, belt presses or centrifiguges. It is significantly less expensive and easier to maintain and operate then the other three, and service life has been proven and time again to be longer.

We specialize in providing our clients with quality made Tube Settler. These tube settlers used for solid-liquid seperation and shall be applied for most industrial applications and water treatment plants. Our settlers not only saves 1/5thof the civil tank area space but also ensure effective setting ot solids and find wide application in drinking water treatment,waste water treatment,Biological floc separation,mining area flood warer treatment,ash handling plants, and Bio solids separation. We also provide our clients with Chevron shaped tube settlers,square tubes with surface area in the tune of 11.0sq.m per m3.